- Research Facilities

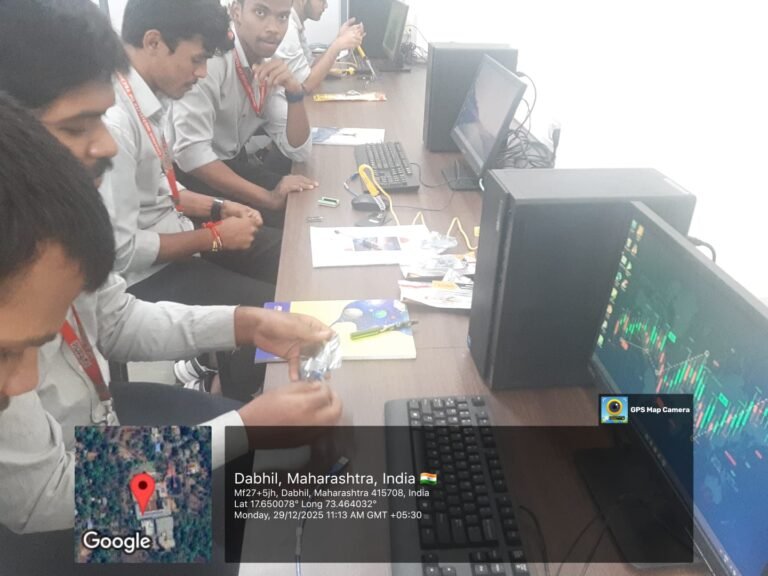

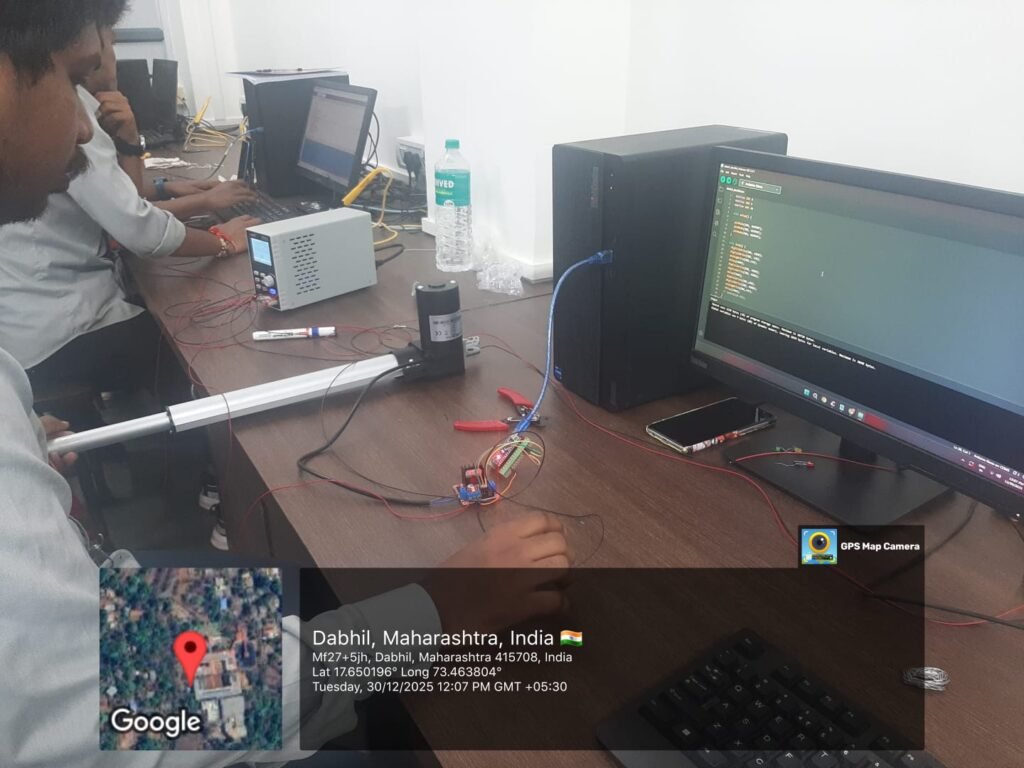

FAB Lab

The FAB Lab of Gharda Institute of Technology plays an important role in promoting research, innovation, and hands-on learning. It provides researchers and students access to advanced tools such as 3D printers for rapid prototyping of mechanical parts and product designs.

PCB designing software enables the development and testing of custom electronic circuits for research projects. A wide range of sensors and actuators supports experimentation in robotics, IoT, and automation systems. Automation-related equipment helps in building and validating control systems and smart machines.

The lab encourages interdisciplinary research by integrating electronics, mechanical, and programming. Researchers can quickly convert ideas into functional prototypes, reducing development time. The FAB Lab also supports projects, academic research, and industry-oriented problem solving. It acts as a platform for innovation and startup ideas.

Overall, the FAB Lab strengthens research culture and practical skill development at the institute.

- Research Facilities

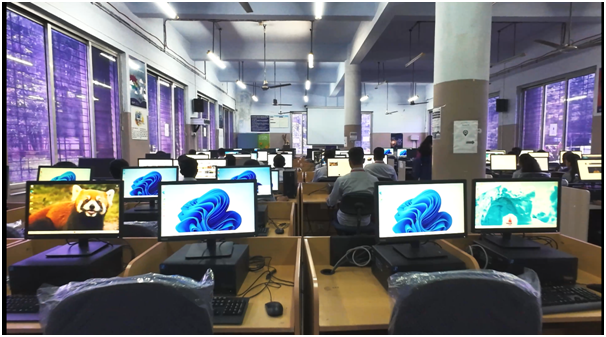

Central Computing Facility

Overview

Established in 2007, the Centralized Computer Centre Facility serves as the core of the GIT campus IT infrastructure. Located on the First Floor of A-Wing, the centre includes two modern computer laboratories, a dedicated Server Room, and the main operational hub of the Computer Centre.

- Research Facilities

ARSST Lab

The Advanced Reactive System Screening Tool (ARSST) facility has been established as a state-of-the-art experimental setup aimed at strengthening process safety, reactive hazard assessment, and safe scale-up practices in the chemical process industries. This facility represents a significant step towards enhancing industry-oriented safety research and testing capabilities.

The ARSST facility has been fully sponsored with a total financial support of ₹42.5 lakh by fourteen nearby chemical industries, reflecting strong industry–academia collaboration and trust in the facility’s relevance. The sponsoring industries include Gharda Chemical Ltd. Lote, Vinati Organics, Laxmi Organics, Excel Industries, USV Limited, Rallis India Ltd, Krishna Antioxidants, SI Group, Deepak Novochem, Kansai Nerolac Paints Limited, Dorf Ketal, Privi Organics, Godrej Agrovet, and Aimco Pesticides. Their collective contribution highlights the growing importance of proactive safety evaluation in modern chemical operations.

The ARSST is an advanced, easy-to-use, and cost-effective adiabatic screening calorimeter designed to rapidly identify thermal and pressure-related hazards associated with chemical reactions. It enables safe and controlled experimentation to evaluate reaction behavior under near-adiabatic conditions, closely simulating real process scenarios. The facility is particularly useful for screening runaway reactions, self-reactive chemicals, and gas-generating systems.

Using the ARSST facility, several critical safety parameters can be accurately determined, including onset temperature of reactions or decomposition, non-condensable gas generation, maximum pressure development, reaction kinetics, rate of temperature rise, and energy release characteristics. These parameters are essential for understanding reaction hazards and for designing appropriate safety measures such as relief systems and emergency controls.

The experimental data generated using ARSST play a vital role in ensuring safe operation of chemical industries. The results assist industries in making informed decisions related to process design, scale-up, risk mitigation, and emergency preparedness. Additionally, the facility supports training, research, and consultancy activities in the field of process safety and chemical reaction engineering.

Overall, the ARSST facility serves as a valuable shared resource for the chemical industry, promoting safer manufacturing practices, compliance with safety standards, and advancement of knowledge in reactive system safety. It stands as a successful model of industry-supported infrastructure dedicated to preventing chemical accidents and fostering sustainable industrial growth.

- Research Facilities

Central Workhop

Workshop Facilities: The Engineering Workshop comprises well-equipped sections such as the Machine Shop, Fitting Shop, Carpentry Shop, Welding Shop, Plumbing Shop, Blacksmithy Shop, and CNC Shop, providing essential hands-on training in manufacturing and fabrication processes.

Utilization:

Practical training for Engineering Workshop–I and Engineering Workshop–II (First Year Engineering).

Practical sessions for Machine Shop and CAD/CAM (Second Year Mechanical Engineering).

Support for mini and major project work of students from Mechanical, Chemical, Civil, and EXTC Engineering, as per project needs.

Assistance for faculty research and PhD work aligned with approved research topics.